Service and Repair Software for CNC Router/mill machine

2026-02-20

- CNC workshops using service and repair software reduce machine failures, delays, and costly breakdowns.

- Skipped servicing, tool wear and unnoticed issues lead to shutdowns and missed production deadlines.

- Automated scheduling keeps every CNC router and mill maintained, calibrated and ready to run.

- AntMyERP handles alerts, work orders and service logs end-to-end, so nothing depends on memory or manual tracking.

CNC routers and mills can go from running perfectly to stopping in an instant. That’s why factories need service and repair software to stay ahead of breakdowns instead of scrambling after them.

Keep the machines cutting, the orders flowing and the pressure off your production line.

Think of it as the brain behind your CNC workshop, tracking every service task before it becomes a crisis.

This platform logs repairs, schedules upkeep and keeps teams aligned without sticky notes or shouting across the floor.

What is service and repair software for CNC Routers and Mills?

Service and repair software is a digital tool that tracks, schedules and manages all the work needed to keep CNC machines running smoothly. Instead of relying on notebooks, scattered spreadsheets or verbal updates everything stays organized in one place.

The software reminds teams when a machine needs servicing, logs every repair done, stores past issues for future reference and lets managers monitor work progress in real time so routers and milling machines stay healthy, productive and breakdown free.

- Central platform for logging jobs

- Stores repairs, calibrations and lubrication details

- Access past records anytime

- Includes repair and maintenance management software workflows

- Works like a modern repair management software tool for all machines

Why CNC Users Need Modern service repair software?

CNC machines are built for precision, so even a tiny glitch can slow down or completely halt production. When maintenance is handled manually, it’s easy to miss tasks, forget follow-ups or react too late especially when multiple machines are running nonstop.

- Prevents sudden shutdowns during busy production times

- Maintains cutting accuracy, speed and tool alignment

- Supports downtime reduction for CNC machines

- Enables real time machine health monitoring

- Makes sure every routine task and service checklist is completed on schedule

According to a report from Gitnux, unplanned downtime costs manufacturers an estimated $50 billion annually, highlighting why proactive maintenance and digital service and repair software are critical to keeping CNC operations running smoothly.

How industrial machine maintenance software Works

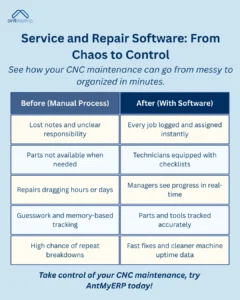

Keeping CNC maintenance on paper can feel like managing chaos in slow motion. With a digital system at the center, every request, technician and task finally falls into a proper rhythm and the shop floor starts running like clockwork.

Imagine this

A CNC router starts making a strange humming sound mid-shift.

Earlier, the operator would have yelled across the floor or scribbled a note hoping someone saw it.

But now, he logs a ticket in seconds.

- A job is created automatically through work order management

- The nearest technician is assigned with a timestamp

- A checklist opens up for troubleshooting

- The task progress is visible to the manager instantly through CNC task management

- If a bearing needs replacement, the system checks inventory and links spare parts tracking

- When the job is completed, the technician uploads notes and photos

- The record is saved for future inspections, feeding smarter preventive maintenance for CNC machines

What once took two days of “Who’s handling this?” now becomes a 30-minute, error-free workflow.

No missed calls, no lost memory, no mystery failures, just clean, predictable maintenance in motion.

Challenges Without Digitized Maintenance

When maintenance tracking lives in paper files or WhatsApp messages, issues slip through the cracks. CNC machines lose productivity long before the failure becomes visible.

- Lost service records lead to guesswork

- Sudden breakdowns due to skipped lubrication

- Missing or unavailable critical parts

- No clear scheduling visibility

- Blockages in spare parts tracking

- Expensive CNC router repair service dependence

- Technicians, especially a CNC router technician, face delays

Key Features to Look for in CNC maintenance software

The best CNC platforms support field, shopfloor and back-office operations equally well. Factories should evaluate features based on scalability and machine complexity.

- Drag-and-drop PM calendar and auto reminders

- AMC, calibration and service contract tracking

- Technician routing, checklists and proof-of-work

- Asset tagging for tools and parts

- Supports CNC tool management software needs

- Functions like a heavy equipment management system

Benefits of Using Modern repair management software

Digitization delivers measurable operational and financial impact that ripples across the plant.

- Longer CNC lifespan by planned upkeep

- Lower emergency repair expenses

- Less machine idling and higher output

- Faster response to job requests

- Transparent cost-control and reporting

Why Businesses Choose AntMyERP for repair and maintenance management software

AntMyERP offers CNC plants a connected maintenance hub that keeps every machine healthy, whether you operate a small router shop or a multi-machine milling floor.

- Assigns jobs instantly to field technicians

- Tracks AMC, warranty and service history

- Automates preventive maintenance schedule

- Controls inventory with reorder alerts

- Logs downtime, failure patterns and expenses

- Built-in billing, quotations and reporting

Explore what our customers are saying about their CNC maintenance success, read our customer testimonials here.

Performance Analysis with Digital Maintenance

When CNC maintenance data lives in one place, decision making moves from reactive to strategic. Performance can be monitored continuously thus improving both reliability and cost efficiency.

- Uptime vs downtime comparison

- Technician efficiency and average repair duration

- Trending recurring faults

- High wear part mapping

- Real dashboards support machine health monitoring

Future Trends in CNC Maintenance

CNC maintenance is moving toward intelligent decision making powered by automation and integrated technology. Companies using digital systems are already ahead of the curve.

- Predictive forecasting through AI and IoT

- Sensors that self-flag anomalies

- Cloud based factory visibility

- Remote troubleshooting and virtual support

- Unified CNC plus field team workflow platforms

Industries That Benefit from CNC Service and Repair Software

CNC routers, mills and other precision machines are now standard across multiple sectors. These industries gain the most value from adopting service and repair software for smoother workflows, reliable uptime and lower breakdown risk:

- Furniture and Woodworking Manufacturing

High-volume routing, carving and shaping demand consistent machine performance. - Automotive and Auto Components

Precision machining for gears, molds, frames and custom metal parts makes maintenance essential. - Aerospace and Defense Engineering

Safety and quality standards require tight tool calibration and no unplanned downtime. - Industrial Maintenance Industry

Handles preventive upkeep and fixes for CNCs and other heavy machines across multiple sites. - Power Equipment Industry

Requires structured service schedules, available spares and technician tracking for mission-critical machinery.

Conclusion

Investing in service and repair software gives CNC workshops more than organized schedules, it transforms maintenance into a predictable, efficient and cost saving process. With real time visibility, reduced downtime and smarter decision making, factories unlock higher output from every router and mill.

AntMyERP enables businesses to manage maintenance, spares and technicians without chaos, helping CNC machines run longer, safer and more profitably.

Keep your CNC machines running at peak performance. Start managing maintenance smarter with AntMyERP today!