Logistics Management software for CNC Laser Cutting machine

2026-02-25

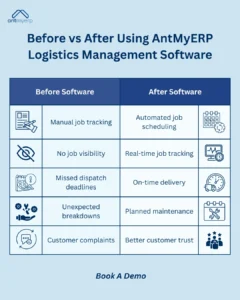

Managing CNC laser cutting logistics manually leads to missed jobs, delayed dispatch, and machine downtime. Logistics management software helps CNC businesses plan jobs, track materials, manage maintenance, and deliver orders on time all from one system.

A CNC laser cutting unit receives an urgent order.

Material arrives late. The machine is available, but the job schedule is confusing. The dispatch team has no idea when the job will finish. Result?

Delayed delivery

Angry customer

Extra cost

This is a logistics problem, not a machine problem.

That’s where logistics management software becomes essential for CNC laser cutting businesses.

Why Logistics Is a Big Challenge in CNC Laser Cutting?

CNC laser cutting is not just about cutting metal sheets with a machine. Behind every successful cut, there is proper planning, tracking, and coordination.

In real life, a CNC job passes through many steps:

- Raw material must arrive on time

- The machine must be free and working properly

- The job must be scheduled correctly

- Finished parts must be packed and dispatched without delay

As per Business Research Insights the global supply chain and logistics software market is growing fast. More companies are investing in automation, real-time tracking, and data-driven planning to manage operations better and avoid delays.

When even one step fails, the entire job gets delayed.

Most CNC laser cutting businesses face these common logistics problems:

- Jobs are not scheduled properly

Many workshops still use Excel sheets or verbal instructions. This creates confusion about which job should run first and which machine is available. - Raw material delivery is delayed

Without logistics tracking, material often arrives late or in the wrong quantity, causing machines to sit idle. - Finished parts are dispatched late

When job completion time is not tracked, dispatch teams don’t know when orders are ready, leading to missed delivery deadlines. - No tracking of job status

Managers and customers keep calling for updates because there is no real-time visibility of job progress. - Machine maintenance is ignored

Maintenance is usually done only after a breakdown, which suddenly stops production and affects all scheduled jobs. - Reverse logistics becomes messy

Handling rework, rejected parts, or returned orders becomes difficult because there is no proper system to track what went wrong and why.

Because of these issues, CNC businesses lose time, money, and customer trust even when their machines are perfectly capable.

This is exactly why a structured logistics management software is needed to bring everything under control.

What Is Logistics Management Software?

Logistics management software helps businesses:

- Plan and schedule jobs

- Track materials and deliveries

- Monitor job progress in real time

- Handle reverse logistics smoothly

- Reduce manual follow-ups

For CNC units, it connects machines, jobs, people, and dispatch in one system.

How Logistics Software Helps CNC Laser Cutting Businesses

1. Job Scheduling Made Simple

Using job scheduling software, you can:

- Assign jobs based on machine availability

- Avoid overloading machines

- Track job start and completion time

A job scheduling app for contractors ensures nothing is missed.

2. CNC Machining Logistics Under Control

With proper CNC machining logistics, you can:

- Track raw material movement

- Monitor WIP (Work in Progress)

- Plan dispatch accurately

This improves overall CNC workflow management.

3. Real-Time Logistics Tracking Software

Logistics tracking software helps you:

- Track job status live

- Know which order is delayed

- Share accurate updates with customers

No more phone calls or guesswork.

4. Machine Maintenance Is No Longer Ignored

Unplanned breakdowns delay jobs. Using annual machine maintenance contract software, maintenance tracking system, and annual maintenance contract software you can:

- Schedule preventive maintenance

- Reduce sudden downtime

- Keep CNC machines ready

This directly supports preventive maintenance software goals. For more insights on maintaining and managing heavy equipment effectively, check out our guide on high-tech construction equipment management software.

5. Reverse Logistics Made Easy

Handling rework or returned parts is painful without data.

Reverse logistics software helps track:

- Returned jobs

- Rework reasons

- Cost impact

This improves quality and customer trust.

Why AntMyERP’ Logistic Software the best for CNC Logistics Management?

AntMyERP is designed for manufacturing and machine-based businesses.

It works as:

- Logistics management software

- Job scheduling app

- Task management software

- Field service management software

All in one platform.

Key Features of AntMyERP for CNC Businesses

- Job Scheduling & Tracking

- Machine Maintenance Management

- Logistics & Dispatch Tracking

- Task Management Software

- Analytics & Reports

- Reverse Logistics Tracking

Analytics & Future Trends of Logistics & Dispatch Tracking software in CNC Logistics

With analytics, you can:

- Identify delay reasons

- Track machine utilization

- Improve delivery timelines

Future CNC businesses will rely on:

- Data-driven scheduling

- Predictive maintenance

- Integrated logistics software for small business

Industries That Benefit the Most from Logistics Management Software

- CNC laser cutting units

- Sheet metal fabrication

- Heavy machine workshops

- Contract manufacturing

- Small & mid-size manufacturing businesses

Customer Testimonial

“We realized we didn’t have the right ERP we needed to run the company optimally. We were using a lot of independent softwares to run Operations, Sales, Support, HR but AntMyERP offered us everything we needed with many capabilities to grow into as the company grew. With AntMyERP, we’ve been able to improve profit by cutting costs. AntMyERP has helped us become a more profitable operation. On-time processes have improved by 33%, while staff efficiency & accountability has improved considerably.”

— Mr. Tushar Parekh, Managing Director, Silicon Netsecure Pvt. Ltd

Conclusion

CNC laser cutting businesses don’t fail because of machines.

They fail because of poor logistics planning.

By using the AntMyERP’s best logistics software, helps you:

- Deliver jobs on time

- Reduce downtime

- Improve customer satisfaction

- Grow your business confidently

Want to simplify CNC job scheduling and logistics? Try AntMyERP Logistics Management Software today.