How QR Code Maintenance Improves Preventive Equipment Maintenance in CMMS

2026-02-27

- QR code–based maintenance ensures timely preventive servicing, real-time asset visibility, and reduced downtime.

- Without it, missed inspections, delayed servicing, and lost spare parts cause costly disruptions.

- Scanning QR codes links every machine, tool, and part to the CMMS, instantly updating maintenance logs, inventory, and work orders.

- AntMyERP streamlines this entire workflow with alerts, preventive schedules, QR-based job cards, and audit-ready logs thus eliminating reliance on memory or manual follow-ups.

Maintenance teams often know something needs servicing but not what, when or where.

Paper logs fade, spreadsheets get outdated and busy teams rely on memory rather than data.

That’s when breakdowns hit, assets fail mid operation and costs skyrocket.

Modern CMMS platforms now integrate QR code maintenance, giving every asset a scannable identity.

Technicians just scan the QR code onsite using a mobile device to access asset history, log maintenance tasks, raise issues or check pending work, all instantly synced to the system.

Industry Insight:

According to statistics from Stacker, in 2025, 71% of maintenance teams rely on preventive maintenance, but only 58% of facilities follow schedules consistently. Integrating QR code maintenance with a CMMS helps close this gap by keeping tasks on track and assets fully visible.

What Is QR Code Maintenance in CMMS?

QR code maintenance means tagging equipment with scannable QR labels that link to digital asset profiles inside a CMMS.

How it works inside CMMS:

- Every asset receives a unique QR tag

- The QR code stores a link to the asset’s CMMS record

- Scanning pulls up maintenance history, manuals, and schedules

- Technicians update jobs on the spot

- All changes sync back into the system automatically

Why Preventive Maintenance Needs QR Codes

Most breakdowns happen because preventive tasks never happen on time. Manual processes make it worse.

Common challenges without QR systems:

- Technicians struggle to identify assets correctly

- Schedules get missed due to poor reminders

- Maintenance data remains outdated

- Inconsistent logging leads to blame shifting

QR code maintenance solves these problems by:

- Ensuring every asset is uniquely tagged

- Making information instantly accessible

- Removing guesswork or delays

- Helping teams detect issues early

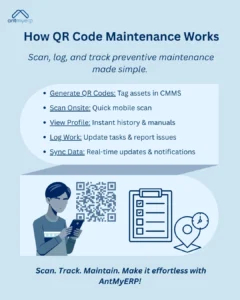

How QR Code Maintenance Works (Step-by-Step)

A technician enters a factory one day in the morning.

The machine used for production is making weird sounds.

He goes directly to the machine instead of going through the files, making calls or looking for the paperwork, he takes his mobile phone out of his pocket and scans the QR code attached to it.

This fast scan activates the whole maintenance process.

Step 1: Generate QR Codes

Before this day, every asset was tagged with a unique QR label from heavy machinery to small pumps and even spare parts.

Each QR code is linked to the machine’s digital profile inside the CMMS.

Step 2: Technician Scans the Code Onsite

The technician scans the QR code using his phone.

No barcode scanners.

No laptops.

Just the mobile app he already carries.

Within seconds, the CMMS recognizes the asset.

Step 3: CMMS Opens the Asset Profile

A complete equipment record loads instantly.

The technician can now see:

- Maintenance history

- Recent failures or breakdown patterns

- Make/model details and user manuals

- Warranty and vendor contact info

He knows exactly what has happened with this machine in the past, no guesswork.

Step 4: Log Work Instantly

The technician performs the scheduled inspection and updates everything on the spot.

With one tap, he can:

- Close the pending work order

- Upload photos of the noisy part

- Report abnormalities for supervisor review

- Add condition notes like “bearing worn, replace next week”

Everything is recorded right where it matters.

Step 5: CMMS Syncs Live Data

As soon as he taps Save:

- The dashboard updates in real time

- Managers see the issue without waiting for paperwork

- Preventive schedules automatically adjust

- Other technicians get notified if further repairs are required.

The technician walks away knowing the job is logged, risks are documented, and future maintenance is already aligned.

Key Features of QR Code Asset Management

QR coding transforms asset handling from reactive to controlled.

Core Features:

- Unique digital identity for every asset

- Scan-based service processes

- Cloud-based record storage

- Lifecycle tracking from installation to disposal

What teams gain

- Faster identification

- Zero ambiguity on which asset needs service

- No misplaced tools or undocumented equipment

- Clear audit trails for compliance

Benefits of QR Code Equipment Tracking

QR tracking solves one of the biggest maintenance mysteries: Where is the equipment now, and what’s its condition?

Enables:

- Tracking location across sites

- Understanding run hours and wear patterns

- Identifying overdue maintenance

- Preventing asset hoarding or loss

- Alerting teams before breakdowns

- Keeping maintenance cycles on schedule

- Prioritizing critical assets automatically

QR Code Inventory Management for Maintenance

Imagine walking into a storeroom and instantly knowing which parts are available without searching around.

Inventory makes or breaks any maintenance plan.

QR-coded inventory delivers:

- Real-time part visibility

- Stock updates as items are used

- Automatic reorder triggers

- Linking spares directly to work orders

Outcomes:

- Lower downtime waiting for parts

- Reduced overspending

- No “lost” items at the back of a shelf

- A working qr inventory system that stays accurate

QR Code Maintenance Requests

When a machine shows unusual signs of wear, a quick scan can raise a maintenance request instantly.

Technicians shouldn’t chase supervisors to report problems.

With QR-based requests:

- Scan then Report issue then Auto-create job

- Attach photos for clarity

- Assign tasks instantly

- Reduce errors in communication

Benefits:

- Faster resolution

- Better prioritization

- Zero overlooked failures

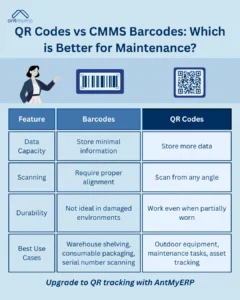

QR Codes vs CMMS Barcodes: Which is Better for Maintenance?

QR Codes for Business Maintenance Operations

Across multiple sites, standard processes ensure no asset or maintenance task is overlooked.

Whether managing one building or ten sites, QR codes standardize processes.

Business-wide advantages:

- Uniform digital records

- Consistent execution across branches

- Faster onboarding of new staff

- Easier audits and compliance proof

Perfect for:

- Construction fleets

- Factories

- Hospitals

- Rental equipment companies

- Facilities and utilities

Implementation Best Practices

Getting QR code maintenance right requires thoughtful execution.

Best practices:

- Tag all critical assets first

- Use strong industrial-grade labels

- Place codes where they are easy to scan

- Build scan-first workflows

- Train field teams early

- Automate preventive schedules

How AntMyERP Enables QR Code Maintenance

AntMyERP bridges QR scanning and CMMS automation seamlessly.

What AntMyERP offers:

- QR-based asset management with lifecycle tracking

- Real-time equipment tracking across locations

- QR-linked inventory management and stock syncing

- Mobile-first maintenance requests triggered by scan

- Preventive schedule automation

- Dashboards, logs, and audit histories

- Connected field-to-office maintenance workflows

One platform replaces spreadsheets, scattered reports, and manual follow-ups.

“We realized we didn’t have the right ERP we needed to run the company optimally. We were using a lot of independent softwares to run Operations, Sales, Support, HR but AntMyERP offered us everything we needed – with many capabilities to grow into as the company grew. With AntMyERP, we’ve been able to improve profit by cutting costs. AntMyERP has helped us become a more profitable operation. On-time processes have improved by 33%, while staff efficiency & accountability has improved considerably.”

— Mr. Tushar Parekh

Managing Director, Silicon Netsecure Pvt. Ltd

Performance Analytics & Future Trends in QR Code Maintenance

QR code maintenance is not just about scanning and updating, it unlocks powerful maintenance intelligence when paired with a CMMS.

How Performance Analytics Adds Value:

- Track preventive vs reactive maintenance ratio

- Measure technician performance and job completion speed

- Identify top breakdown causes across assets

- Spot downtime trends and improvement opportunities

- Forecast part failures based on service patterns

Future Trends Shaping QR Code Maintenance

- AI-powered maintenance planning:

Predict which assets are likely to fail before schedules even trigger. - IoT and QR code convergence:

Equipment sensors capture live data while QR links provide instant access. - Digital twins and asset simulation:

CMMS systems model asset behavior to advise on maintenance strategies. - Fully paperless field service:

From job dispatch to sign-off everything happens via QR-linked mobile workflows.

Industries That Benefit Most from QR Code Maintenance

QR code maintenance isn’t limited to heavy industries; any business with assets, tools or inventory can use it.

Industry Sectors Seeing Immediate Gains:

- Manufacturing plants

- Construction companies

- Equipment rental & leasing

- Healthcare and hospitals

- Facilities & commercial buildings

- Food & pharmaceutical companies

- Utilities and infrastructure

- Warehousing & logistics

Conclusion

QR codes transform maintenance by connecting assets, inventory and technicians in one digital ecosystem.

With every scan updating real-time data, preventive maintenance becomes predictable, repeatable and cost efficient.

Ready to modernize preventive equipment maintenance?

Explore AntMyERP and see how QR code maintenance simplifies operations from plant to field.