Annual Maintenance Contract Software for Heavy Machine India

2026-02-16

- When you manage yearly service deals yourself, things can get messy. Overlooked appointments, slow fixes, missing documents tend to increase expenses while bringing extra stress.

- Using Annual Maintenance Contract Software means each asset, whether a tool or agreement, stays recorded online. Updates show up automatically ensuring preventive maintenance happens on time, downtime is minimized, and spare parts are always accounted for.

- With AntMyERP AMC, alerts get automated along with task, preventive scheduling, plus logs ready for audits – this way, maintenance teams rely less on personal recall, scattered notes, or outdated spreadsheets.

Why Manual AMC Management Fails?

Example: A construction company has multiple sites, each with heavy machines like diggers, hoists, power units. Workers see delays coming, though records live in separate places, timing feels unclear, supplies do not arrive fast enough. Paperwork is scattered, schedules are confusing, and parts are missing. In the middle of work, a tool stops functioning, target dates slip away, expenses climb sharply.

Here’s how things shift when you bring in annual maintenance contract software – processes get smoother, data stays organized, preventive work moves without obstacles.

What Is Annual Maintenance Contract Software and How It Works

AMC software is a tool that manages all your service contracts digitally.

It tracks:

- Contract start and end dates

- Scheduled preventive maintenance

- Maintenance history for each asset

- Spare part inventory

- Work orders and service requests

What matters most, it ensures Heavy industrial equipment providers that construction machines, and rental fleets are always maintained on time, well-maintained – on schedule – with zero need for people to log each step.

As per a published article Organizations that adopt AMC strategies supported by software report measurable gains up to 30% cost reduction and 20% productivity improvements because preventive work replaces costly reactive repairs.

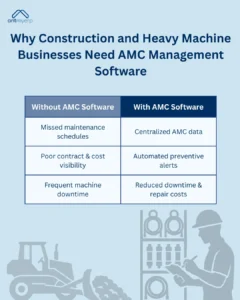

Why Businesses Need AMC Management Software for Annual Maintenance Contracts

Pain Points Without AMC Software:

- Missed maintenance schedules

- Hard to manage equipment service contracts across sites

- Poor visibility of costs, spare parts, and service history

- Frequent downtime and surprise failures

How AMC Software Helps

- Centralizes annual maintenance contract system data

- Sends automatic alerts for preventive maintenance

- Tracks machine lifecycle management and construction equipment maintenance

- Creates audit-ready logs

- Reduces downtime and repair costs

How AMC Software Works (Step by Step)

A technician shows up at the building construction site. The crane gives trouble. He does not have to look for papers or dial around – this worker opens the AMC app on their phone:

Step 1: Register Assets and Contracts

Every machine from a large excavator to small tools is registered in the system with its annual maintenance contract.

Step 2: Automated Scheduling

The software schedules preventive maintenance and sends alerts before service is due. No one has to remember dates.

Step 3: Onsite Work and Logging

The technician performs the inspection or repair and updates everything instantly in the app:

- Close work orders

- Upload photos of the issue

- Add notes on the condition of the machine

Step 4: Inventory Updates

Spare parts used are logged automatically. If stock is low, the system triggers reorders.

Step 5: Analytics and Dashboards

Managers can check:

- Maintenance completion rates

- Equipment downtime trends

- Costs per machine

- Compliance with service contracts

The result? Everyone knows what was done, when, and on which machine. No guesswork, no delays.

Key Benefits of Using AMC Software for Annual Maintenance Management

For Maintenance Teams

- Clear schedules prevent missed inspections

- Real-time data reduces reliance on memory

- Quick access to machine history, manuals, and spare part info

For Business Owners

- Less downtime means higher productivity

- Better control of maintenance costs

- Audit-ready logs for compliance

For Operations Across Industries

- Construction companies: Manage heavy machines and operators efficiently

- Equipment rental companies: Track rental AMCs and condition reports

- Industrial equipment companies: Streamline machinery and equipment industry operations

As per Worldmetrics.org Companies that implement preventive maintenance programs (often supported by AMC or CMMS software) experience significant reductions in equipment downtime in some cases up to 30% or more.

How AntMyERP AMC Software Simplifies Annual Maintenance Contract Management

AntMyERP brings all AMC tasks into one platform:

- Centralized AMC management software with preventive schedule automation

- Real-time tracking of industrial equipment

- Inventory management synced with service tasks

- Mobile-friendly interface for technicians on-site

- Dashboards and audit-ready logs in one place

Testimonial

AntMyERP has improved our day to day rental operations. There has been a noticeable shift in our company since we implemented AntMyERP. With its industry-specific solution, our inventory, reservations, and customer engagements are now easily manageable.

We manage many customers with customer demand specific rental agreements, reports and plan deliveries and pickups.

We are able to get accurate information on laptop availability with a real-time tracking system, it enhances customer satisfaction and increases our operational efficiency.

The customer support team is always responsive, has expertise, and is ready to help.

— Mr Anil Bhavnani, Founder & CEO, Rank Computers

![]()

Key Features of a Modern AMC Management Software

- Automated alerts & preventive maintenance schedules

- Work order management & job card automation

- Equipment lifecycle tracking

- Inventory & spare part management

- ERP integration for centralized operations

Future Trends in Annual Maintenance Contract Software

- AI-powered predictive maintenance: Predict failures before they happen

- Mobile-first access: Update jobs in real time on-site

- IoT integration: Monitor machine condition 24/7 and catch problems early.

- Data-driven insights: Track maintenance trends, costs, and technician performance

Industries That Benefit from Annual Maintenance Contract Software

- Construction & Heavy Equipment

- Industrial Equipment Companies

- Equipment Rental & Leasing

- Medical Equipment Rentals & Hospitals

- HVAC, Managed Print Service, Elevators

- Solar Panel

Conclusion

Managing AMCs manually is risky. Managing AMCs manually is risky. With AntMyERP, AMC Maintenance Contract Software, each task right from planning to creating work orders, tracking stock, then generating reports – becomes easier. This way, those responsible for maintenance spend time fixing equipment instead of getting bogged down by documents.