CNC Machine preventive maintenance checklist

2025-11-05

Preventive maintenance of CNC machines is the only ticket to high productivity and precise operations in a fast-paced world of manufacturing. CNC machines, which are used in cutting, milling, and drilling machines working in high-speed and high-precision operations, form the backbone of modern manufacturing. With great precision comes greater responsibility. Even the most sophisticated CNC systems can give way to sudden breakdown, huge repair costs, and a loss of productive hours without proper care and a well structured preventive maintenance checklist in place.

Hence, a proper maintenance checklist is all-important. AntMyERP simplifies this process by automating, tracking, and managing maintenance schedules through its Preventive Maintenance Software thus keeping every machine in top shape for production with minimal downtime.

Why Maintenance of CNC Machines Matters

Looking into CNC machines are made for long hours of precision work, be it a rotating machine, milling machine, or router, every part of it, be it the spindle or the coolant system, is kept under pressure. Over time, the pressure mounts and wear and tear are the result.

Preventive maintenance helps find small issues before they become big issues. Maintenance teams also take a proactive approach in taking care of their machines through maintenance rather than waiting for something to break, assisting with performance, extending the life of the equipment and meeting safety standards.

Types of Preventive Maintenance in CNC Operations

Time-Based Maintenance: Maintenance on set dates, on a daily, weekly or monthly basis, irrespective of use.

Usage-Based Maintenance: Related to hours of machine operation or production cycles.

Condition Monitoring: Observes real-time data like vibration, temperature and lubrication levels to show any early problem indications.

Predictive Maintenance: It estimates the time said component will fail by means of analytics and sensors.

Total Productive Maintenance (TPM): Entails having the operators responsible for their machines as a way of achieving zero breakdowns.

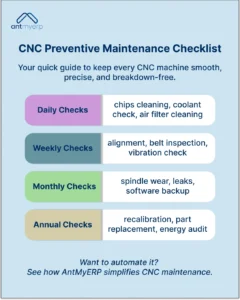

CNC Preventive Maintenance Checklist

A good CNC preventive maintenance checklist should contain:

Daily Checks

- Cleaning the machine’s coolant, chips, and other surfaces.

- Checking the levels of lubricant and coolant.

- Checking and cleaning air filters for dust and debris.

Weekly Checks

- Alignment and calibration of tools.

- Belt, hose, and lubrication system inspection.

- Keep an ear out for any indications of strange vibrations or sounds.

Quarterly or Monthly Checks

- Check for wear within the spindle and chuck.

- Check for leaks in hydraulic and pneumatic systems.

- Check software settings and back up configurations.

- All maintenance activities should be logged with emphasis on recurring issues.

Annual Checks

- Full recalibration of the machine.

- Replacement of damaged and worn out components.

- Energy audit and performance check to spot inefficiencies.

Advantages of Preventive Maintenance in CNC Machining

Adopting a preventive maintenance plan brings both immediacy and delayed benefits such as:

- Decreased Downtime: Determine faults before production can be stopped.

- More Accuracy: Maintenance ensures continuous alignment and calibration of machining.

- Less Expensive: Preventive maintenance avoids expensive repairs and unnecessary parts replacement.

- Long Life of Machine: Regular maintenance would protect components from wear, corrosion and failure.

- Increased Productivity: Keeps machines working without hassle and continuously.

- Better Record Keeping: Maintenance logs will give patterns on the timing of the interventions.

A well organized maintenance program not only boosts performance but also builds long term reliability and trust in your production quality.

How AntMyERP Simplifies CNC Maintenance Management

Managing multiple CNC machines manually can get chaotic like missed schedules, incomplete records and delayed servicing can lead to major issues. AntMyERP removes all that hassle by bringing automation and structure to your maintenance process.

Here’s how AntMyERP helps simplifies CNC maintenance:

- Automated Scheduling: Creation and assignment of maintenance work orders or tasks automatically based on calendar or usage.

- Real-Time Monitoring: Monitor spindle hours and coolant levels and vibration data in real-time to preempt any occurrence of further issues.

- Predictive Analytics: AI alerts warn the technicians ahead of time of a breakdown.

- Mobile Access: Technicians in the field can log maintenance work, upload pictures and mark tasks as done.

- Centralized Records: All service histories, requests for spare parts and inspection reports are kept together in one place.

- Custom Templates: Develop maintenance checklists specific to CNCs on a per machine model basis.

By combining these tools, AntMyERP helps manufacturers shift from reactive maintenance to proactive performance ensuring every CNC machine operates at peak efficiency.

Conclusion

In today’s time manufacturers can’t afford downtime and preventive maintenance remains the smartest way to avoid it. A structured CNC preventive maintenance checklist ensures steady output, fewer breakdowns and a longer machine lifespan. Pairing that strategy with AntMyERP lets you automate the process, track performance in real time and make data driven decisions that keep your machines running at their best.

Keep your systems efficient, your schedules on time, and your production seamless. That’s the power of preventive maintenance with AntMyERP!