The Operational Reality of Managing Emission Testing Equipment Across Multiple Locations

2026-01-23

Managing emission testing equipment across multiple locations can be hard. Missed maintenance, scattered records, and poor tracking create stress and audit problems.

AntMyERP provides field service management, preventive maintenance, and AMC management software to centralize operations, track assets, automate maintenance, and ensure audit-ready service documentation across all locations.

Imagine overseeing three emission testing centers in different areas. Machines are running, technicians are busy, and reports are generated daily. From the outside, everything looks fine.

But when auditors arrive:

- Calibration records are missing

- Preventive maintenance is skipped

- Service logs across locations are scattered

Suddenly, operations that seemed fine are flagged for non-compliance.

This is the operational reality of managing emission testing equipment across multiple locations and highlights the importance of emission testing equipment management.

Challenges of Multi-Location Emission Testing Operations

Managing multiple locations is not easy. Teams find it hard to coordinate service, do preventive maintenance on time, track calibrations, and keep records ready for audits. Without a central system, mistakes and compliance risks increase

- Disconnected centralized asset database across sites

- Inconsistent equipment service traceability

- Delays in calibration tracking for emission equipment

- Missed preventive maintenance schedules

- Difficulty producing audit-ready service documentation

As per Gov Capital, Digital asset management systems improve organization, accessibility, security, and traceability, which can support regulatory compliance and make audits smoother.

Why Multi-Location Emission Testing Operations Need Software

Field service teams often rely on memory, emails, or Excel sheets to track equipment. Preventive maintenance is manual, and audits become stressful. Without proper emission equipment service management, businesses risk audit failures, regulatory penalties, and increased downtime.

- Lack of centralized visibility

- Manual tracking increases errors

- Compliance gaps in service history

- SLA and AMC contracts are hard to monitor

- Reactive maintenance increases operational risk

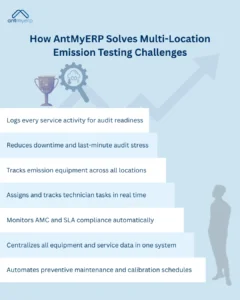

How AntMyERP Helps in Managing Emission Testing Equipment

AntMyERP centralizes multi-location operations and automates service management for emission testing centers. Using field service management, preventive maintenance, and AMC management software helps businesses run smoothly, avoid downtime, and stay ready for audits without any last-minute stress.

Field Service Management for Emission Equipment:

- Centralizes service across locations

- Tracks technician task assignments in real time

- Automatically logs service for audit-ready documentation

- Automates maintenance schedules

- Tracks calibration history for emission equipment

- Ensures maintenance is never missed

- Tracks service contracts across sites

- Monitors SLA compliance

- Maintains digital records for audits

Companies using AntMyERP have seen measurable improvements in their service management.

As Mr. Jignesh Patel from ArMee Infotech Limited shares:

AntMyERP has streamlined our operations efficiently, exceeding our expectations.

AntMyERP’s Service Module in our ERP system has significantly improved our service management processes. The user-friendly interface and comprehensive features helped us to manage our services seamlessly. The robust ticketing system enables us to efficiently create, track, and resolve service requests. The automated workflow ensures accountability and accuracy within our team, as well as advanced analytics and reporting tools, empowering us to optimize our service delivery strategies for better customer satisfaction.

Customizable Service Module made AntMyERP a scalable solution for our business needs, ensuring exceptional service management capabilities as we grow. We highly recommend AntMyERP for always ready to help customer support.’

Operational Reality at multi-location emission testing center:

At a multi-location emission testing center, machines functioned perfectly, yet audit day revealed gaps: missing calibration records, delayed preventive maintenance, and scattered service logs. Before AntMyERP, operations were reactive and stressful. After implementation, everything became centralized, automated, and audit-ready.

- Equipment may function but documentation is critical

- Centralized records reduce audit stress

- Preventive maintenance automation ensures uptime

- Real-time updates improve technician coordination

Before vs After: Multi-Location Management

Before AntMyERP:

- Records scattered across Excel sheets

- Preventive maintenance often missed

- Audits stressful, documentation incomplete

- SLA compliance handled reactively

- Technician tasks unmanaged

After AntMyERP:

- Centralized asset database accessible across all locations

- Automated preventive maintenance & calibration tracking

- Audit-ready service documentation instantly available

- SLA compliance monitored with alerts

- Real-time technician task assignment

AntMyERP’s Features & Benefits

AntMyERP provides a full-stack solution for multi-location emission testing operations. It brings all service management into one place, automates preventive maintenance, keeps SLA compliance on track, and gives real-time insights.

- Centralized Asset Management: track lifecycle of every device.

- Preventive Maintenance Automation: scheduled tasks per equipment.

- Real-Time Field Updates: technicians log work via mobile app.

- AMC & SLA Tracking: contract and compliance monitoring.

- Analytics & Reporting: service performance analytics, uptime tracking, multi-location equipment monitoring.

Future Trends: Data-Driven Audits

Audits are moving from checklist-based to data-driven. Regulators increasingly require:

- Digital service histories

- Real-time visibility across locations

- Predictive maintenance insights

- Multi-location equipment monitoring

- Facilities relying on manual systems face growing compliance risks

- AntMyERP ensure maintenance compliance tracking

- Real-time dashboards improve operational decisions

Industries That Benefit Most

Any facility operating emission testing equipment across multiple sites benefits from centralized service management.

- Vehicle emission testing centers

- Power plants

- Industrial manufacturing units

- Testing and calibration laboratories

Conclusion

Managing emission testing equipment at multiple locations is not easy. Without a central system, maintenance can be missed, audits can fail, and operations can run into problems. AntMyERP helps by tracking assets, automating maintenance, and keeping service records ready for audits, while giving you a clear view of everything.

- Centralized emission testing equipment management reduces audit risks

- Automated preventive maintenance ensures uptime

- SLA and AMC management ensures compliance

- Real-time updates improve technician coordination and operational efficiency

Make managing your multi-location emission testing equipment easier. Book a demo of AntMyERP Field Service Management to keep all assets and service records organized and audit-ready