Heavy Equipment Maintenance Software for Defense Industry

2026-01-24

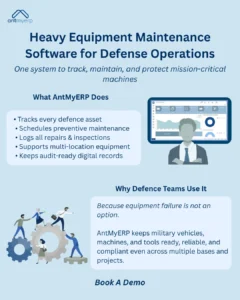

Heavy equipment maintenance software for the defense industry helps military teams keep track of their assets, plan maintenance in advance, and avoid unexpected breakdowns.

AntMyERP makes it easier to manage defense equipment by keeping all service records, inspections, and repairs in one place. This helps teams stay ready for operations, pass audits without stress, and control maintenance costs.

With software for field service, asset tracking, and equipment lifecycle management, AntMyERP supports companies dealing with defense units in keeping their machines reliable, available, and mission ready.

Why Maintenance Cannot Fail in Defense Operations?

In defense operations, a machine breaking down is not just a small problem it can slow down work and even put people at risk. Imagine a military base where an important piece of equipment stops working in the middle of a task because its maintenance records are missing or scattered. Technicians then have to waste time searching for service details, booking repairs, and finding spare parts.

When a machine breaks, the work doesn’t just slow down, everything gets disturbed. Jobs get delayed, costs increase, and teams stop trusting the equipment. That’s why maintenance cannot be complicated. AntMyERP stores all machine details in one place, so teams don’t have to dig through files to find past repairs. It’s easy to see what needs to be checked or fixed. This way, problems are handled early, and there’s no panic when inspection time comes.

What is Heavy Equipment Maintenance Software for the Defense Industry?

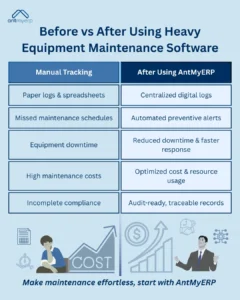

Heavy equipment maintenance software helps defense teams keep their machines in working condition. Instead of searching through piles of paper or old spreadsheets, teams can keep track of a machine’s service and repairs in one spot. You always know what’s been fixed and what needs attention next. You can see when it was last serviced, what was repaired, and what is due next.

This helps teams fix things before they break down. Machines last longer, and there are fewer surprises that slow down daily operations.

As per Globenewswire Digital tools that track maintenance, predict problems, and schedule repairs are now a must. The defense equipment maintenance market is expected to grow from USD 75.1 billion in 2025 to USD 124 billion by 2034, showing how militaries are modernizing maintenance practices.

How the Maintenance Process Works

First, all vehicles and machines are added into the system and given a unique ID. This helps the team quickly find any equipment and see where it is being used.

After that, maintenance dates are set. The preventive maintenance software sends reminders when a machine needs service, based on its usage, last repair, or the company’s maintenance rules.

When a job is due, technicians receive the work on their phones. They check the machine, do the repair or inspection, and update the status right there. This removes the need for paper forms or later data entry.

A technician scans a military loader with the maintenance app. Right away, they can see what’s been fixed, what still needs attention, and mark the tasks they just completed. This keeps the machine running smoothly and avoids unexpected downtime.

Types of Heavy Equipment Maintenance Software for Defense:

- Field Service Management: Give jobs to technicians and see what they are doing.

- Repair & Maintenance Tracking: Repair and Service tracking software track repairs and keep track of parts.

- Preventive Maintenance: Get alerts before machines break.

- Rental / Multi-Location Management: With Rental Software see where all machines are, even in different places.

- Defense & Military Equipment Lifecycle Management: Tracks equipment from the time it’s bought until it’s retired, helping teams stay ready and compliant.

Why AntMyERP is the Best Solution for Defense Maintenance

AntMyERP’s Machine Equipment Maintenance Software is a complete platform that helps defense teams keep their heavy equipment in shape. You can give tasks to technicians and check what they’re doing on the spot. Repairs get logged right away, spare parts are easy to track, and recurring maintenance doesn’t get forgotten.

The software also helps keep an eye on each machine from the day it’s bought until it’s retired. Digital records keep everything organized, making audits easier.

Teams can stay on top of maintenance, keep machines running, and prevent unexpected breakdowns.

Benefits of Using Heavy Equipment Maintenance Software in Defense

- Schedule maintenance so machines don’t break down unexpectedly.

- Get alerts when something needs attention.

- Track repairs, parts, and labor to avoid extra costs.

- Use dashboards and mobile apps to see what’s happening easily.

- Keep digital logs ready for audits.

Companies dealing with defense equipment using AntMyERP noticed a decline in unplanned equipment failures within the first three months. Technicians get alerts on their phones for maintenance work. Repairs are updated right away, and managers can see all machines in one place. This helps teams work faster and keeps all compliance records ready.

Real-World Workflow: How Heavy Equipment Maintenance Software Transforms Defense Operations

1.Asset Tagging & Records: Every machine gets its own ID, usually a QR code or barcode. The software keeps track of who made it, what fixes were done previously, and roughly when it will need its next check.

2. Preventive Maintenance Scheduling: The software also reminds the team when the machine needs servicing. It shows at hours used, last repair, or what the manufacturer says. Supervisors can see what is coming up and tell technicians what to do next.

3. Technician Work: Technicians scan the equipment with their mobile app, do inspections or repairs, and mark it as done.

4. Monitoring & Reporting: With Monitoring & Reporting features, Managers can check the dashboard to see which machines are running okay and which ones are giving trouble. If something looks wrong, an alert shows up so the team can fix it before it becomes a bigger problem.

This way, the team can avoid unexpected breakdowns, make better use of their time and resources, and keep machines ready when they’re needed.

Industries That Benefit

- Defense & Military: They need machines ready all the time. This software helps track repairs, plan maintenance, and keep equipment working longer.

- Defense Contractors: When equipment is in many places, it’s hard to know what needs fixing. This system shows where each machine is and reminds the team when maintenance is due.

- Construction & Heavy Equipment Rentals for Defense Projects: Big projects have machines at lots of places. With this software team can see where the machines are, which ones are in the most used category, and helps prevent sudden breakdown when you need them.

List of more industries we serve

How Rental Companies Benefit from Heavy Equipment Maintenance Software

Rental companies that supply defense equipment deal with many challenges. Their machines are spread across different locations, they must follow strict rules, and the equipment always needs to be ready for use. AntMyERP addresses these challenges effectively:

Key Benefits for Rental Companies:

- Multi-Location Asset Tracking: Teams see where all your rented machines are, even if they’re spread across different clients, bases, or projects.

- Preventive Maintenance for Rentals: The system reminds you when a machine needs a check or service, so it doesn’t break unexpectedly.

- Condition & Usage Monitoring: Keep track of how much each machine is used and what repairs it’s had. This helps you make smarter decisions when renting them out.

- Operational Readiness: This helps in making sure every piece of rented equipment is ready to go. Fewer breakdowns mean happier clients and less downtime.

- Audit & Compliance: Everything is logged digitally, so audits and compliance checks are easier to handle.

- Optimized Resource Allocation: You know which machines are available, which ones need maintenance, and can plan your resources better.

A rental company tracking armored vehicle equipment across multiple bases can schedule preventive maintenance, log repairs, and monitor availability, reducing downtime and ensuring mission readiness for clients.

Analytics & Future Trends in Defense Maintenance

According to Defense Equipment Maintenance, Repair And Overhauling (MRO) The defense equipment maintenance market is increasingly using data analytics, sensor technologies, and predictive maintenance to anticipate failures and optimize service schedules, making maintenance more proactive and reliable.

What Our Customers Say

AntMyERP has streamlined our operations efficiently, exceeding our expectations.

AntMyERP’s Service Module in our ERP system has significantly improved our service management processes. The user-friendly interface and comprehensive features helped us to manage our services seamlessly. The robust ticketing system enables us to efficiently create, track, and resolve service requests. The automated workflow ensures accountability and accuracy within our team, as well as advanced analytics and reporting tools, empowering us to optimize our service delivery strategies for better customer satisfaction.

Customizable Service Module made AntMyERP a scalable solution for our business needs, ensuring exceptional service management capabilities as we grow. We highly recommend AntMyERP for always ready to help customer support.

Mr. Jignesh Patel, Manager – Operations, ArMee Infotech Limited

Conclusion

Heavy equipment maintenance software is important for defense operations. AntMyERP helps track repairs, manage field service, and control the full asset life cycle.

Book a demo to reduce downtime, use equipment better, and stay mission ready.