How Poor Asset & Service Traceability Can Fail Emission Equipment Audits (Even If Operations Look ‘Fine’)

2026-01-19

Poor asset management and weak service traceability can cause emission equipment audits to fail even when machines work perfectly. Missing service logs skipped preventive maintenance, and manual tracking increase compliance risks. AntMyERP solves this with complete asset traceability, preventive maintenance software, and audit-ready documentation.

When “Everything Looks Fine” Until Emission Equipment Audit Day

On a normal working day, your emission testing facility feels under control. Machines are running. Technicians are busy. Reports are being generated. From the outside, operations look perfectly fine. But when an external audit team arrives, the reality suddenly changes.

They ask simple questions:

- Where is the calibration history of this emission analyzer?

- When was the last preventive maintenance done?

- Can you show the complete service log for this equipment?

Suddenly, files are missing. Excel sheets don’t match. Technicians rely on memory instead of records.

This is how poor asset management and poor asset & service traceability quietly cause emission equipment audit failures even when daily operations seem smooth.

Why Emission Equipment Audits Have Strict Compliance Requirements

Emission equipment is not ordinary machinery.

It directly impacts:

- Environmental safety

- Regulatory compliance

- Public health

That’s why auditors don’t just check whether machines are working.

They check proof.

Audits demand:

- Complete asset traceability for emission equipment

- Accurate equipment service logs

- Timely calibration records

- Preventive maintenance history

- Compliance with regulatory timelines

If even one record is missing, it creates serious equipment audit compliance risks.

How Poor Asset & Service Traceability Causes Emission Equipment Audit Failures

Many businesses assume: “Our equipment is working, so audits won’t be a problem.”

This is the biggest misconception.

Common Service Traceability Issues

- Maintenance done but not recorded

- Service logs scattered across Excel sheets

- Calibration dates tracked manually

- No centralized asset history

- Records lost when staff changes

When auditors review your systems, memory doesn’t count, documentation does.

Real Audit Failure Example Caused by Poor Asset Management

A vehicle emission testing center had all machines operational. Daily tests were conducted without issues.

But during the audit:

- Calibration records were incomplete

- One analyzer had no service history for six months

- Preventive maintenance dates didn’t match actual service dates

Even though the equipment worked perfectly, the audit result failed .Because audit failure is about traceability, not appearance.

How Poor Asset Management Leads to Audit Failure

1. No Central Asset Database

Without proper asset management software, equipment details remain scattered across files, emails, and people’s memories.

2. Missed Preventive Maintenance

Without preventive maintenance software, schedules depend on manual reminders leading to delays or skipped services.

3. Incomplete Equipment Service Logs

Missing or inconsistent service logs raise immediate red flags during audits.

4. No Regulatory Compliance Tracking

Without regulatory compliance tracking, businesses react after issues arise rather than preventing them.

Why Auditors Care More About Records Than Machines

Auditors ask one key question: “Can you prove this equipment has been maintained correctly?”

If you cannot:

- Show accurate service logs

- Prove timely calibration

- Track asset history

Then operational performance becomes irrelevant. This is why many audit failure examples involve fully functional equipment but poor documentation.

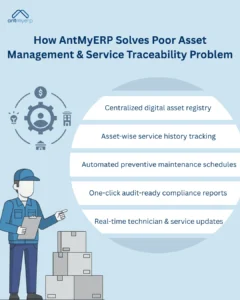

How AntMyERP’s Asset Management Software Solves This Problem

1] Complete Asset Traceability

Every emission equipment has a digital profile:

- Installation date

- Calibration history

- Service records

- Compliance status

2] Automated Preventive Maintenance

Using built-in preventive maintenance software:

- Schedules are auto-generated

- Technicians are assigned

- Tasks are logged automatically

No missed dates. No forgotten services.

3] Digital Equipment Service Logs

Every inspection, repair, or calibration is:

- Recorded in real time

- Stored centrally

- Instantly accessible during audits

4] Regulatory Compliance Tracking

AntMyERP ensures:

- Compliance deadlines are monitored

- Audit-ready reports are generated

- Risks are identified before audits

Before vs After: Asset & Service Traceability

Before Using Software

- Before adopting a digital system, asset records are usually scattered across Excel sheets and paper files.

- Service logs are maintained manually and often remain incomplete or inconsistent.

- Preventive maintenance is frequently missed because there are no automated reminders or schedules in place.

- During audits, teams feel stressed and unprepared due to missing records and unclear service history.

- Compliance tracking is handled reactively, only when an issue or inspection arises.

After Using AntMyERP

- After implementing AntMyERP, all asset records are stored in a centralized digital system that is accessible in real time.

- Service logs are automatically updated whenever maintenance or repairs are performed, ensuring complete traceability.

- Preventive maintenance is fully automated with alerts and schedules, reducing breakdowns and downtime.

- Audit readiness becomes confident and controlled, with all documents and histories available instantly.

- Compliance tracking turns proactive, with timely reminders, checklists, and documented proof always in place.

According to Gov Capital, digital asset management systems keep asset records organized, easy to access, and fully traceable. This reduces manual mistakes and helps teams stay audit-ready with clear, time-stamped records.

Why AntMyERP helps in Emission Equipment Compliance

AntMyERP’s Asset management software and AMC Management software is built for industries where compliance is non-negotiable.

Key Benefits:

- Centralized asset management

- Reliable service traceability

- Audit-ready documentation

- Reduced regulatory penalties

- Improved equipment uptime

Industries That Benefit Most

- Vehicle emission testing centers

- Power plants

- Industrial manufacturing units

- Testing & calibration labs

Future Trend: Audits Are Becoming Data-Driven

Audits are no longer checklist based. They are data driven.

Future audits will demand:

- Digital service histories

- Real-time compliance visibility

- Predictive maintenance data

Businesses relying on manual systems will face increasing regulatory compliance risks. Our asset software supports audit-ready asset and service traceability with real-time data and automated compliance tracking.

Client testimonial:

USAM Technology Solutions Pvt Ltd – AntMyERP has played a crucial role in optimizing our business operations through the automation of various processes. Its comprehensive suite of functionalities, ranging from financial management to inventory control, has significantly improved our efficiency and productivity.

The intuitive and user-friendly interface of AntMyERP has facilitated a seamless transition for our team, enabling them to navigate and leverage the software without the need for extensive training. This has resulted in an immediate enhancement of our overall workflow.

The automation of invoicing and expense tracking has not only saved us valuable time but has also minimized errors, providing us with a more accurate and transparent financial overview.

One standout aspect of AntMyERP is its exceptional customer support. The team is highly responsive and proactive. Any queries or concerns are promptly addressed. AntMyERP stands out as a crucial business management tool, We recommend it to any organizations in search of an efficient system for their business needs.

– Mr Saravanam S, Deputy Manager, USAM Technology Solutions Pvt Ltd

Conclusion: Asset Traceability Is the Key to Passing Emission Equipment Audits

In emission equipment audits, looking fine is not the same as passing.

If you don’t have:

- clear asset traceability

- proper service documentation

- up-to-date preventive maintenance records

With AntMyERP, you move from last-minute, reactive compliance to audit-ready operations every single day with complete records, automated maintenance, and zero guesswork.