The Evolution of Mobile CMMS Solutions: Trends and Innovations

2026-02-04

- Maintenance used to be a total headache: paper logs piling up, scattered spreadsheets, nonstop phone calls. Now with Mobile CMMS, things just work better. Technicians pull up work orders, track assets, and update tasks right on their phones or tablets.

- They solve problems quicker and keep things running without the usual chaos. With tools like automation, predictive maintenance, and smart analytics, Computerized Maintenance Software takes a lot of the hassle out of the job.

- AntMyERP wraps all of this into one simple app, so teams stay organized and actually feel on top of their work.

The Maintenance Challenges Before CMMS software

The machine stopped during peak hours. The technician asked for the last service record. The supervisor checked Excel. The data was outdated. Spare parts were missing. Everyone waited. Production loss started within minutes. This situation is still common in many companies. Not because teams are careless but because maintenance systems are outdated.

This is why CMMS Software has become important.

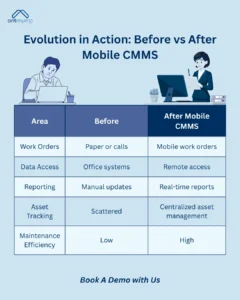

The Rise of Mobile CMMS: From Manual to Digital

Mobile CMMS is maintenance software you can use right on your phone or tablet. It lets teams manage work orders, check asset details, handle preventive maintenance, and pull up reports while they are on the field at client location.

Instead of depending on registers or office computers, teams get remote access to maintenance data at all times.

Limitations of Traditional Maintenance Methods

Many maintenance teams still depend on manual processes like:

- Paper logs

- Excel files

- Phone calls for approvals

These methods often lead to:

- Missed preventive maintenance

- Poor equipment maintenance history

- Delayed work orders

- No clear maintenance visibility

Mobile maintenance management fixes these issues by keeping everything connected.

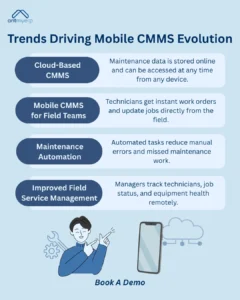

Trends Driving Mobile CMMS Evolution

1] Cloud-Based CMMS Is Now the Standard

With cloud-based CMMS, maintenance data is stored safely online. Teams can access updated information from any device without waiting for reports.

2] Computerized Maintenance Management Software for Field Teams

Technicians receive tasks instantly through mobile work orders. Job updates, photos, and notes are added directly from the field.

3] Maintenance Automation Reduces Manual Errors

With automated maintenance, there is no less chance of errors and stress about forgetting jobs or messing things up by hand.

4] Better Field Service Management

Managers can track technician work, job status, and equipment health without visiting the site.

Adoption and Productivity Gains in Mobile CMMS

Grand View Research Shows Preventive Maintenance Software adoption is growing, driven by needs for real-time work orders, improved communication, and reduced response times.

Global Growth Market Insights indicate that mobile-enabled CMMS can boost technician productivity by up to ~40%, as field workers can access and update work orders on the go.

Common Maintenance Pain Points and Solutions

Without Computerized Maintenance Management System:

- Slow breakdown response

- No real-time asset management

- Frequent equipment failure

- Poor communication

With Mobile CMMS:

- Faster work order handling

- Updated maintenance records

- Better planning

- Improved workflow automation

Innovative Features Driving Mobile CMMS Evolution

- Mobile device integration

- Preventive maintenance scheduling

- Asset management

- Data synchronization

- Workflow automation

- Maintenance analytics

- Equipment maintenance records

These CMMS features help teams work faster with fewer mistakes.

How Computerized Maintenance Management System Improves Daily Maintenance Work

When technicians use mobile solutions, they spend less time calling supervisors and more time fixing problems.

Managers get clear visibility. Data stays updated. Decisions become easier.

The result is better maintenance efficiency and reduced downtime.

Why Choose AntMyERP Mobile CMMS?

AntMyERP’s Mobile CMMS is built for practical maintenance needs, not just dashboards.

How AntMyERP Helps Maintenance Teams:

- Easy-to-use mobile maintenance software

- Strong asset management system

- Cloud-based CMMS access

- Reliable field service management

- Clear reports and analytics

It supports growing teams without adding complexity.

Sectors Where Mobile CMMS Is Widely Used

- Power and Energy

- Healthcare facilities

- CNC and heavy equipment

- IT and Telecom

- EV and infrastructure services

Any business that relies on equipment maintenance can benefit.

What Users Say:

The Next Stage: Future Innovations in Mobile CMMS

Maintenance teams are moving towards:

- Predictive maintenance

- Advanced maintenance analytics

- Higher maintenance automation

- Better mobile device integration

PM Software will continue to lead this change.

The Evolution of Mobile CMMS is Here

Maintenance teams cannot afford delays caused by manual systems.PM software gives teams control, visibility, and speed.

AntMyERP helps businesses move from reactive maintenance to structured maintenance management.

Explore AntMyERP Preventive Maintenance software by Booking Demo and see how modern maintenance teams work smarter.