Predictive Maintenance vs Preventive Maintenance: Key Differences Outlined

2025-11-19

In any industry, Machines are the lifelines for industrial operations. Maintaining machines and keeping them running smoothly each day isn’t easy. When machines break down suddenly, production stops and costs rise. That’s why companies often compare predictive vs preventive maintenance to find which works best for them.

In basic terms, predictive maintenance utilizes data and sensors to find when a machine could fail and operation could stop, while preventive maintenance uses fixed Preventive schedule or time-based maintenance plan to avoid such failures in industrial operations.

Understanding the difference between preventive and predictive maintenance helps businesses save costs, reduce downtime, and keep their operations running efficiently.

According to the Forbes Technology Council, “unplanned downtime costs more than you think” with industrial manufacturers facing losses of up to US $50 billion annually.

What is Predictive Maintenance?

Predictive maintenance is a condition-based maintenance smart method that helps in predicting equipment issues before something goes wrong. It uses predictive analytics maintenance tools so that Sensors collect real-time data like temperature, vibration, and pressure from the equipment. This real time data is analyzed using predictive analytics to detect patterns that show when a machine could fail. By using predictive analytics maintenance tools and predictive equipment maintenance methods companies avoid extra repairs and cost and keep the machines running smoothly without surprise breakdowns.

According to a report by McKinsey & Company, predictive maintenance can reduce machine downtime by 30-50% and extend the lifespan of aging assets by 20-40%.

Example:

In a manufacturing plant, vibration sensors are installed on machines. When they detect unusual vibrations, the system alerts the team to replace the bearing before it fails. This approach supports downtime reduction strategies and leads to better maintenance cost optimization.

What Is Preventive Maintenance?

Preventive maintenance is a planned maintenance system that involves only time-based maintenance or schedule-based approach. It follows a time-to-time servicing and inspecting of machines at regular intervals every month or every 500 hours of use even if they seem to be working fine.

Common tasks include cleaning, oiling, adjusting, and replacing worn parts. This method is also called planned or time-based maintenance.

As per the study done by Plant Engineering, 78% of companies use preventive maintenance as a key part of their maintenance programs.

For example, hospitals using preventive maintenance software for maintaining their MRI machines and other equipment.

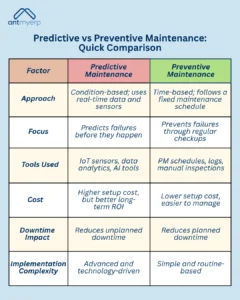

Preventive vs Predictive Maintenance: Key Differences

Both methods aim to reduce downtime and improve equipment efficiency, but they differ in how and when maintenance is performed.

Here’s the predictive preventive maintenance difference explained in simple words:

Approach:

- Predictive maintenance collects real-time data by using predictive analytics for machine maintenance conditions. It first finds out how equipment is actually performing and shows when a machine could fail.

- Preventive maintenance, on the other hand, follows a time-based fixed schedule. It has a proper timeline schedule for regular intervals, whether the machine needs it or not.

Goal:

- The goal behind predictive maintenance is to find even the smallest problems as early as possible before any sudden breakdowns that stop work or cause expensive repairs. It uses data and machine signals to warn technicians when something is not right.

- Preventive maintenance pays attention to keeping equipment in good working shape through regular checkups, cleaning, and servicing. Machine Maintenance is scheduled on dates to avoid sudden failures and keep operations running smoothly.

Tools Used:

- Predictive maintenance uses sensors, IoT, and predictive analytics.

- preventive maintenance depends on maintenance logs, PM schedules, and manual inspections.

Cost:

- The implementation of Predictive maintenance is an advanced task and quite complex. But Provides better ROI.

- The set up of Preventive maintenance is easier and more manageable in terms of ROI.

Implementation:

- The implementation of Predictive maintenance is quite advanced and complex. But Provides better ROI.

- The set up of Preventive maintenance is easier and more manageable in terms of ROI.

Downtime Impact:

- Predictive maintenance helps the maintenance team in avoiding unexpected machine breakdowns by finding problems early, that means unplanned downtime.

- With Preventive maintenance, teams do not need to stress about unexpected downtime as everything is scheduled as per calendar.

Maintenance Strategy:

- Predictive maintenance is a data-driven maintenance optimization approach, while preventive maintenance follows a fixed planned maintenance system.

- This explains the difference between preventive maintenance and predictive maintenance and helps businesses choose the best maintenance plan for their assets.

Choosing the Right Maintenance Strategy

When it comes to choosing the ideal maintenance, the strategy depends on industry vertical, budget in place, and the type of equipment they use.

If the business involves high-value machinery with sensors, predictive maintenance is an ideal choice and best for asset maintenance optimization and minimizing unexpected failures.

If Industry operations are simple, following a fixed servicing routine, preventive maintenance or a time-based maintenance plan may fit better.

Some companies even combine both using preventive maintenance for routine care and predictive maintenance for critical assets.

The goal is to reduce downtime, improve maintenance optimization, and extend machine lifespan.

Predictive and Preventive Maintenance Examples

Predictive Maintenance Example: In an industrial plant, predictive analytics software keeps track of how the conveyor motor is working. If it gives some sound or strange vibration patterns, Software picks the pattern and alerts the maintenance team. It helps to look into it and fix the issue before the machine stops working.

Preventive Maintenance Example: In hospitals, engineers follow a set PM schedule. They regularly clean and check medical equipment to make sure everything stays safe, reliable, and ready to use for patients.

These examples show that both predictive and preventive maintenance play an important role in keeping machines in good shape and reducing unexpected downtime.

Businesses can simplify both predictive and preventive maintenance with AntMyERP Preventive Maintenance Software. It provides automated PM scheduling, asset tracking, and predictive analytics tools to identify issues before failure. With everything managed in one dashboard, AntMyERP helps teams save time, reduce maintenance costs, and keep assets running efficiently.

Final Thoughts

When companies choose between predictive maintenance vs preventive maintenance, it is not about choosing one. This needs the right balance as per operation demand, so your machines keep running smoothly without any trouble.

When using both, It gives a strong maintenance to reduce costs, improves uptime, and maximizes efficiency.

Whether your goal is maintenance cost optimization or downtime reduction strategies, both methods can work hand-in-hand to keep your assets performing at their best.