CMMS vs. Traditional maintenance: Which Approach is better?

2026-02-18

CMMS software handles all the busywork for you right from tracking work orders, keeping an eye on assets, managing spare parts, and planning maintenance. Machines stay healthier, the team spends less time chasing paperwork, and costs don’t spiral out of control. For a growing business, it’s a no-brainer. In This guide we will compare CMMS vs. Traditional Maintenance

Last month, a factory manager got a midnight call. One machine had broken down. The service record was missing. No one knew when it was last serviced. Spare parts were not available.

The result?

- Production stopped for 6 hours

- Orders got delayed

- The customer was angry

This is a common problem in traditional maintenance.

Now imagine the same situation with alerts, service history, and spare parts details already on your screen. That is the power of CMMS software.

Maintenance is not just about fixing machines. It is about managing maintenance, keeping records, planning service, and avoiding breakdowns.

Today, companies use two main approaches:

- Traditional maintenance (manual methods)

- CMMS maintenance management (digital software)

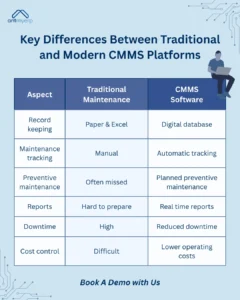

Traditional Maintenance vs CMMS: Key Differences You Should Know

Traditional maintenance means managing equipment using:

- Paper registers

- Excel sheets

- Phone calls and WhatsApp messages

- Manual files for records

This method depends heavily on people and memory.

It works for small setups but becomes risky when assets and jobs increase.

Pain Points of Traditional Maintenance:

- Lost service records

- No preventive maintenance schedule

- Delayed work orders

- No real-time reports

- Higher breakdown maintenance cost

What Is CMMS Software?

A CMMS (Computerized Maintenance Management System) is a digital maintenance management software that helps you:

- Track equipment maintenance

- Manage work order management software

- Plan scheduled maintenance

- Handle spare parts management

- Create maintenance reports automatically

It becomes a complete asset management tool for your maintenance teams.

CMMS Advantages and Disadvantages

Advantages of CMMS:

- Improves efficiency

- Streamlines operations

- Reduces breakdowns

- Better maintenance plans

- Easy maintenance tracking

- Faster work order processing

According to recent preventive maintenance research, companies that implement preventive maintenance programs can reduce equipment downtime by around 35% and decrease unplanned downtime significantly.

Disadvantages of CMMS

- Initial setup cost

- Training needed for staff

- Internet or system dependency

But compared to long-term losses from breakdowns, these limits are small.

Traditional Maintenance vs CMMS: Hidden Costs of Manual Maintenance

Traditional methods may look cheap, but they create hidden losses:

- No condition based maintenance

- Missed routine maintenance

- Poor maintenance processes

- No backup of records

- High repair cost during emergencies

Traditional Maintenance vs CMMS vs ERP: What’s the Difference?

- ERP manages finance, HR, sales, and inventory

- CMMS focuses only on equipment maintenance and assets

- Traditional maintenance means managing equipment using Paper registers and Excel sheets

- CMMS is more detailed and practical for daily maintenance work.

How CMMS Helps in Real Life?

With CMMS software, you can:

- Create preventive maintenance schedules

- Assign jobs to maintenance teams

- Track spare parts stock

- View comprehensive reports

- Monitor asset maintenance history

This helps you move from breakdown maintenance to planned maintenance.

Why AntMyERP for Maintenance Management?

AntMyERP CMMS is designed for Indian industries and service teams.

It helps you:

- Manage maintenance digitally

- Track assets and equipment easily

- Automate work orders

- Plan preventive maintenance

- Generate maintenance reports in one click

It is simple, affordable, and made for growing businesses.

Key Features of AntMyERP CMMS

- Equipment maintenance tracking

- Work order management software

- Preventive maintenance software

- Spare parts management

- Asset maintenance history

- Real-time analytics dashboard

Before vs After Using CMMS

Before Using CMMS (Traditional Maintenance)

Traditional maintenance feels like flying blind. There’s no real preventive schedule, so services are often missed. Machines break down unexpectedly, slowing production. Technicians fill out reports by hand, so errors happen. Service records are scattered in files or Excel, making them hard to track. For the maintenance team Spare parts are easy to locate.

After Using CMMS (Computerized Maintenance Management System)

With CMMS, preventive maintenance runs automatically on schedule. With this software Machine health is monitored on a regular basis which helps in reducing downtime and surprise breakdowns. For the maintenance team Spare parts are easy to locate. Machines are checked regularly, downtime drops, and very less chance of sudden breakdown.

Industries That Benefit from CMMS

- Manufacturing

- CNC & Heavy Machinery

- HVAC & Facility Management

- Healthcare Equipment

- Power & Utilities

- IT & Telecom

Customer Testimonial:

“AntMyERP has streamlined our operations efficiently, exceeding our expectations.

AntMyERP’s Service Module in our ERP system has significantly improved our service management processes. The user-friendly interface and comprehensive features helped us to manage our services seamlessly. The robust ticketing system enables us to efficiently create, track, and resolve service requests. The automated workflow ensures accountability and accuracy within our team, as well as advanced analytics and reporting tools, empowering us to optimize our service delivery strategies for better customer satisfaction.

Customizable Service Module made AntMyERP a scalable solution for our business needs, ensuring exceptional service management capabilities as we grow. We highly recommend AntMyERP for always ready to help customer support.”

— Mr. Jignesh Patel, Manager – Operations, ArMee Infotech Limited

Future Trends in Maintenance Software

- AI-based condition monitoring

- Predictive maintenance

- Mobile CMMS apps

- Cloud-based maintenance systems

Maintenance is moving from reactive to smart and predictive.

Traditional Maintenance vs CMMS: Which Approach Is Better?

When we compare traditional maintenance vs CMMS, the answer is clear.

Traditional methods increase risk, downtime, and cost.

CMMS software helps you:

- Improve efficiency

- Reduce downtime

- Control maintenance cost

- Manage assets better

For modern businesses, CMMS is not an option. It is a necessity. Still managing maintenance manually?

Book a demo for AntMyERP CMMS and bring control, clarity, and confidence to your maintenance operations.