Preventive Maintenance Strategies for Small and Medium-Sized Enterprises

2024-08-13

Over the last few decades, the world has seen an exponential increase in the number of small and medium sized enterprises (SMEs). Maintaining operational efficiency and increasing equipment is of prime importance for their success. Unlike large scale companies, SMEs often work under tight budgets and limited resources. This makes it even more essential to maximize the value of the assets. Sustainable maintenance practices with preventive maintenance strategies can impact the overall productivity, cost efficiency and profitability of the organization.

Preventive maintenance plan refers to the proactive maintenance approach of regularly inspecting and servicing equipment. These maintenance programs help in reducing downtime and chances of unexpected failures. This type of maintenance planning is unlike reactive maintenance which deals with repairs only after equipment failure. The preventive maintenance best practices involve activities such as inspections, cleaning, part replacements etc.

This blog’s purpose is to talk in detail about the preventive maintenance strategies especially for the SMEs. So let us quickly dive into it!

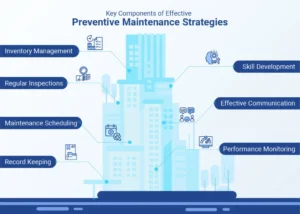

Key Components of Effective Preventive Maintenance Strategies

Let us look at some of the key components of equipment maintenance to get the top-notch efficiency.

Inventory Management

The key to effective preventive maintenance planning is to have a detailed record of all the assets and equipment within the organization. SMEs should maintain an elaborate inventory that includes information of the equipment on model numbers, specifications, purchase dates etc. This will allow for better planning and resource allocation. This ensures that the equipment gets necessary attention to prevent major breakdowns.

Regular Inspections

Scheduled audits and inspections are essential parts of maintenance management. These activities involve examining equipment to identify signs of wear and tear or other potential issues. By regularly inspecting, the SMEs can detect problems early on and address them. This can prevent major breakdowns. Establishing a checklist through preventive maintenance software can help address the issue proficiently.

Maintenance Scheduling

Asset maintenance relies on a well-defined schedule of maintenance tasks. This is customized to the needs of each piece of equipment. These tasks should involve routine activities such as cleaning, calibration, parts replacement etc. The frequency of maintenance operations should be based on usage patterns, manufacturer recommendations and capacity of the equipment. Adhering to such maintenance efficiency increases the lifespan of the equipment.

Record Keeping

Accurate documentation is essential to reap the preventive maintenance benefits. SMEs should maintain a detailed record of the dates, tasks performed, parts replaced etc. This data helps to gauge the performance of the equipment, identify the recurring problems and aid in better decision making for the future. The records help in addressing compliance issues too.

Skill Development

After preventive maintenance implementation, the SMEs should invest in training and skill development that should be on-going. The training should include maintenance techniques, safety protocols, use of preventive maintenance software and so on. By enhancing the skills of the personnel, the organization can ensure that the maintenance tasks are performed with accuracy and proficiency.

Effective Communication

Preventive maintenance is a team activity. Hence, transparent communication amongst the stakeholders carries utmost importance. Effective communication and collaboration is crucial for the success of the program. Regular meetings, sprint calls, and shared maintenance records helps ensure that everyone is aligned and on the same page.

Performance Monitoring

Continuous monitoring of equipment performance and maintenance activities is necessary for improvement. SMEs should implement key performance indicators (KPIs) to measure the effectiveness of the maintenance tasks. KPIs should include metrics like maintenance costs, equipment uptime etc. Regularly reviewing the performance can help in coming up with an effective annual preventive maintenance plan.

Creating Preventive Maintenance Plan

The SMEs should focus on how to create a preventive maintenance plan effectively. Let us look at the points to be considered for the same.

Assessing Current Maintenance Practices

Before creating preventive maintenance strategies, the organization should assess their current situation. This assessment should involve a thorough evaluation of all the machinery, tools and assets used daily. Key factors to consider are the age, condition and the criticality of the equipment. Understanding the current scenario can help in areas of improvement and the areas which would need immediate attention.

Setting Maintenance Objectives

After assessing the current situation, the organization should lay down the goals and objectives of the preventive maintenance plan. The major goals like increasing operational efficiency, reducing downtime and improving the equipment reliability is of prime importance. Specific objectives can be defined by the operations team which also needs to be taken care of. By setting realistic goals, SMEs can better focus on the tasks associated with them.

Creating a Maintenance Schedule

Now comes the time of creating the actual maintenance schedule. This schedule should include all the maintenance activities required for all the equipment. The frequency and timing of the tasks should also be defined. Maintenance schedule should be based on the equipment usage, manufacturer recommendations and other such parameters. The organization should ensure that the schedule is practical and achievable as well.

Allocating Resources and Budget

After the maintenance schedule creation, the organization should pay attention to budgeting and resource allocation. The company should allocate sufficient resources including time, tools and personnel to support the maintenance tasks. It is important to ensure that the maintenance team is adequately trained to carry out the maintenance activities. It should be also kept in mind that the budget can overpower the long term benefits reaped by the organization.

Incorporating Preventive Maintenance Software

To adequately manage the preventive maintenance plan, the SMEs should consider bringing in the maintenance software for help. This software can automate scheduling, tracking, monitoring, etc. By leveraging the preventive maintenance software, the organization can ensure that the preventive maintenance strategies are effectively working. AntMyERP helps you with all your preventive maintenance needs.

Regular Feedback

Even after a maintenance plan is implemented and working, the organization should be open for any feedback. Setting up a review or feedback system can help improve the plan and make necessary changes for the betterment of the SMEs. There is always room for improvement and the regular inspections and audits can help in that.

Using Technology for Preventive Maintenance

Using technology for implementing preventive maintenance strategies can significantly enhance efficiency and reduce operational costs. Softwares like CMMS or EAM systems automates scheduling ensuring that no maintenance tasks are missed. Real time monitoring through IoT devices allows prompt responses to any task that needs attention. These systems also take the help of data analytics to forecast any failure reducing downtime significantly. Additionally, preventive maintenance software allows comprehensive documentation and reporting. This helps in making data-driven decisions and improving preventive maintenance strategies. The integration of these systems with ERP and CRM enables smooth flow of information throughout the organization. Furthermore, cloud based application and mobile accessibility helps the field technicians work on service calls promptly.

To gain the preventive maintenance benefits, the SMEs should intricately select the right software. By adopting these technologies, they can ensure equipment reliability, extend asset lifespan and achieve significant cost savings.

Conclusion

With this discussion, we can clearly see how adopting preventive maintenance strategies can help the SMEs reach their desired operational goals. It will not only help in maximizing efficiency but also help in achieving long-term financial goals. This would further give your organization a competitive advantage over its competitors.

In case you need further assistance in leveraging the state of the art preventive maintenance software, AntMyERP would be happy to help. Let’s get connected!

Next Steps

Book a 15 day free trial with us!

Get the detailed field service software pricing here.

Want to get ensured before you invest? We got you covered! Find the reviews of some of our clients here.